Ford Model t

12 volt starter conversions

July 4th Parade. Not how you want your grand entrance to look after a broken Bendix…

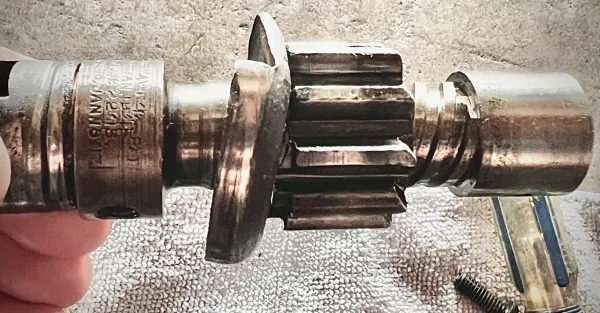

Another VERY common problem using 12 volts on your 6 volt starter is the tiny starter shaft woodruff key gets sheared in half due to the tremendous torque being applied to the bendix by the shaft. This necessitates removing the bendix and replacing the key. Again. Not exactly how I want to spend my evening during a tour.

Here’s the field coil jumper mod after cutting the main input line:

Here’s the brush wires modification. Notice the fiberglass insulator behind the junction:

The new field coil jumper:

The end result is a reliable 12 volt Model T starter that saves your ring gear, bendix and all the other delicate parts in the starting system from abuse and destruction.

These units are made to order and typically take me about a week to complete them.